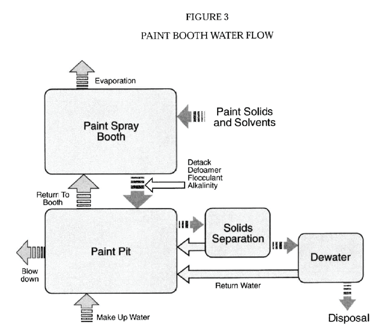

For manufacturing companies that paint large or small articles using water-washed paint spray booth systems, the paint overspray is a challenge to treat. Any paint overspray must be taken out of the air. This is typically accomplished by contaminated air is being pulled to the rear of the paint booth by air exhaust fans while a curtain of cascading water is maintained across the path of the air in such a manner that the air must pass through the water in order to reach to exhaust fans. This paint/air/water mix is then pulled to a sump basin, where the water and paint will be separated.

Paint detackification is the process of treating paint overspray that has been captured by water, the paint is made not tacky by a chemical reaction, thus allowing for paint removal from the water.

If the paint is not detackified, the paint tends to adhere to the sump and drain surfaces, causing issues for manufacturers and their spray booth systems.

Paint overspray can account for 20 – 70% of the total paint sprayed.

If this overspray is not properly detackified:

- Water re-circulation lines and/or pumps become clogged

- Paint adheres to the under booth

- Booth air balance is lost

To prevent clogging of the sump drain and sewer system the accumulated paint must be periodically removed from the sump. This is generally accomplished by shoveling the paint out of the equipment, which is costly and time consuming.

It is preferable to detackify the paint because:

- The paint will not adhere to the surface of the waste paint collection system

- Detackification causes the coalesce of the paint particles, allowing for easy removal

- Separation of the paint solids from the water allows the water to be recycled

- Paint solids can be properly disposed of

Even if paint is properly detackified but is not removed from the paint booth system, serious problems can still occur. Paint provides an excellent growth source for pathogenic and odor producing bacteria. Additionally, paint solids can cause serious foaming, which can cut off the flow of air from the booth.

Different kinds of booths can mean different challenges for paint detackification. There are two types of spray booths discussed in this guide, the Downdraft and the Sidedraft. Different booths mean different air velocities and paths of air flow. This also means there are different places within the booth where detackification and scrubbing occurs, often leading to different methods of recirculating water back into the system.

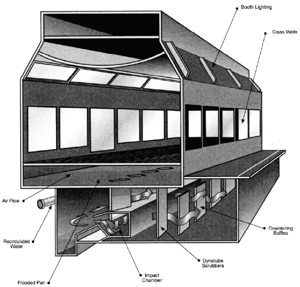

Downdraft Spray Booth:

Air is pumped in through the ceiling and flows down past where the painting is taking place. The paint-laden air flows across a flooded floor pan and down through center slots or tubs (rectangular or circular). As the paint-laden air passes down through this area, the paint is being scrubbed from the air to the water. The air/paint/water mixture is then directed into an impact pond to absorb some of the energy of the mixing, slowing it down and minimizing misting. The scrubbed air is directed through a series of baffles that help to demist the air. This prevents water from leaving the under-booth area. The water from this booth overflows the impact pond, enters a trough and flows to a pit or sump. Paint is normally separated from the water in this area. The paint solids free water is recirculated back to the booth flood pan.

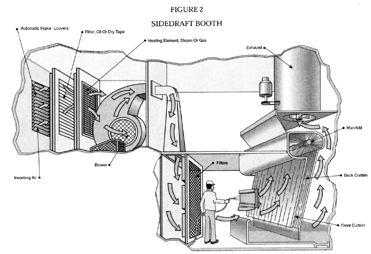

Sidedraft Paint Spray Booth:

Commonly used for painting automobile parts, equipment, and other painted materials. In side draft booths, air enters from one

side of the booth and exits the opposite side. After painting, the overspray laden air is pulled through a curtain of water, which scrubs the paint from the air to the water. The relatively clean air is exhausts through the stack. The water from the curtain falls into a pan and is recirculated back to the top of the water curtain. Water in these booths is laden with paint and need to be cleaned out often. Due to a minimum amount of scrubbing action and limited water flow, this type of booth can be difficult to treat.

Read more about ideal conditions to prevent booth system failure HERE.

Paint overspray that has been detackified will do one of three things: float, sink, or remain dispersed in the paint booth water system. Sludge systems have been designed with each of these concepts in mind. In North America, it is more common to float than disperse the paint. The separation of the paint from the booth water can be floated in a pit and/or again in a consolidation unit. In a booth system that contains a pit, water from the booth enters the pit, at one side, and flows to the far end. At the far end, clean water is pumped from the bottom of the pit and recirculated back to the paint spray booth. The floating paint travels over a weir and is removed from the water in the consolidation unit.

Over the years, as paint formulas have changed, so have the chemical Detackification treatments. Various procedures and techniques have been tried to detackify paint.

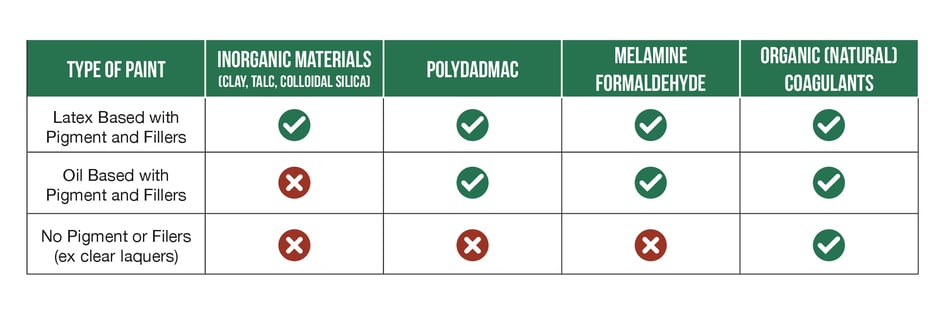

The most difficult paint to treat is paint without pigment or filters. Since there are no solids to provide a base for the detackifying agents to act. Solids-free coating materials are used widely on automobiles because of the increased protection it provides to the finish of the automobile.

The most versatile product for detackifying paint is an organic coagulant combined with a flocculant, since it treats multiple types of paint.

Treating paint over spray with GreenFloc Natural Coagulants will allow:

- To directly replace melamine formaldehyde products used in paint detackification

- Use of half as much product or less when compared to melamine formaldehyde products

- Blending of all natural plant-based materials with metal salts

- Increased water clarity

- Faster solids separation

GreenFloc, a Dober company, can help you maximize the treatment of paint over spray while minimizing your treatment costs.

Click HERE to send us your water to start your treatment plan today.